Product Introduction

Hopcalite catalyst powder is produced by the co-precipitation process of active manganese dioxide and active copper oxide, and has high purity and catalytic activity. It can be used directly or processed into various forms of catalysts, honeycombs, filters and other products.

Product Features

-

No additives, catalytic activity is not disturbed;

-

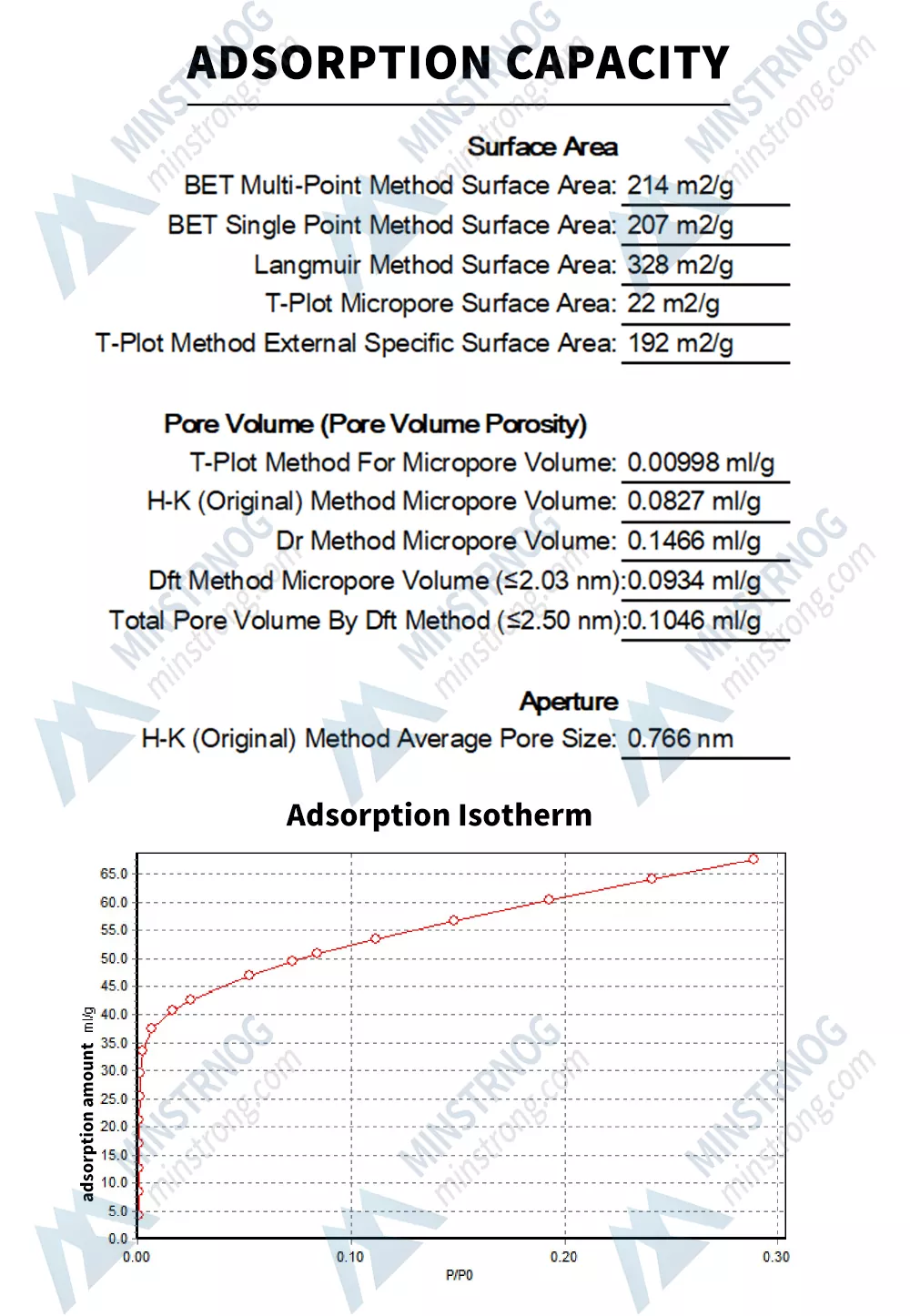

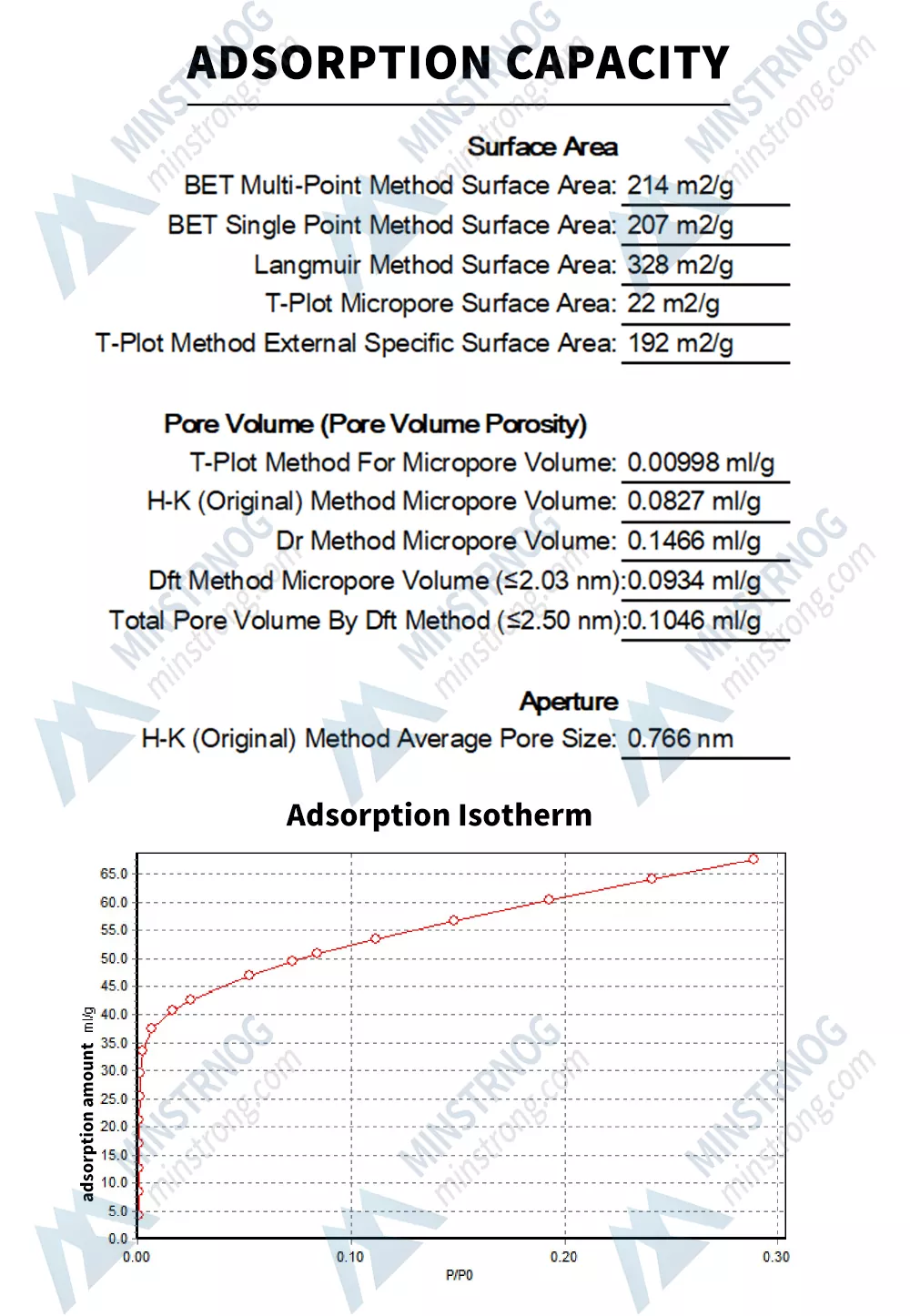

The specific surface area is high, with a specific surface area 160-240m2/g, and a large number of microporous structures are distributed inside the catalyst;

Applications

-

Catalyzes the conversion of carbon monoxide into carbon dioxide at low temperatures, used for compressed breathing air, air separation systems, compressed gas, fuel cells, etc..

-

Decomposes ozone into oxygen without consuming any energy, used for water treatment, air purification, corona machine exhaust purification, plasma equipment exhaust purification, ultraviolet disinfection equipment exhaust purification.

-

Catalytic oxidation of VOC gases such as formaldehyde and ethylene oxide.

-

Catalytic oxidation of hydrogen into water.

-

Catalytic oxidation of hydrogen peroxide into water and oxygen.

-

Used to absorb hydrogen, carbon monoxide, VOC, etc. in a catalytic vacuum environment, used for vacuum insulation boards, vacuum boxes and other equipment.

-

Accelerator for reactions of spices, pharmaceutical intermediates, etc.

-

Adding other ingredients to process into more functional catalyst materials.

-

Direct Use. Directly adding it into the reaction system can maintain the best catalytic activity, obtain the highest catalytic efficiency, and make the reaction proceed at the fastest speed.

-

Granule Catalyst. The catalyst is given a certain shape by using extrusion strips, tablets, etc., which is more convenient to use.

-

Honeycomb Catalyst. The catalyst powder can be coated on the surface of ceramic honeycomb, aluminum honeycomb, etc., or mixed with activated carbon to make activated carbon honeycomb to produce low-resistance catalyst.

-

Filter. It can be coated on non-woven fabrics, sponges and other materials to make filter screens for easy use in air ducts.

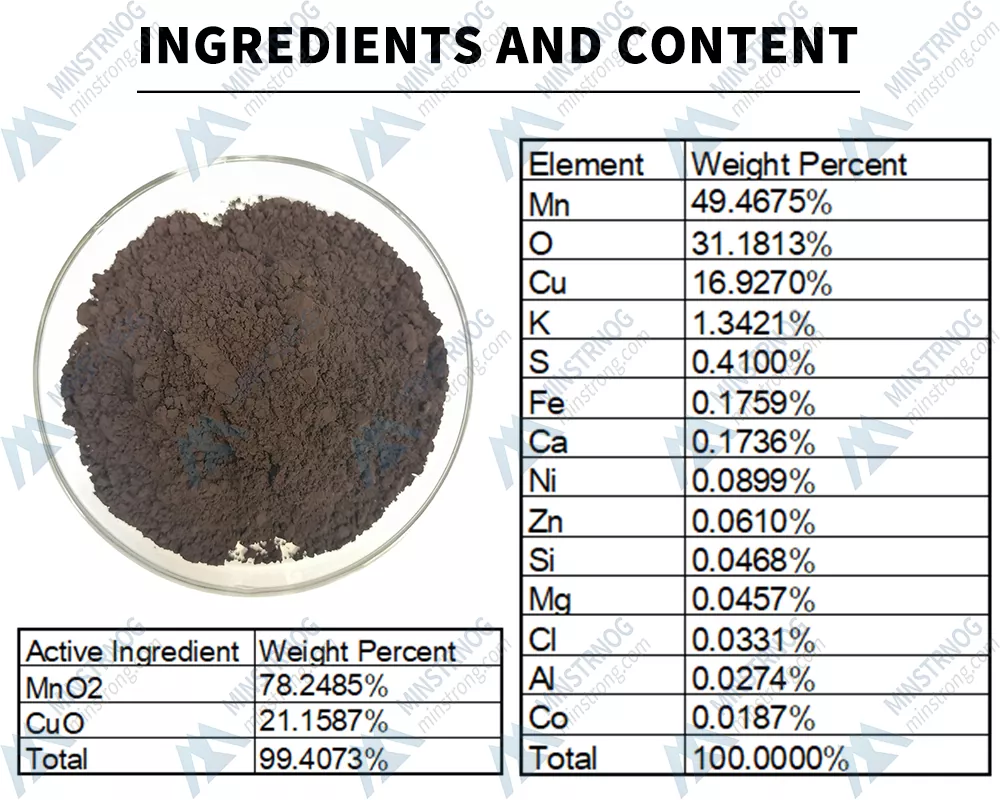

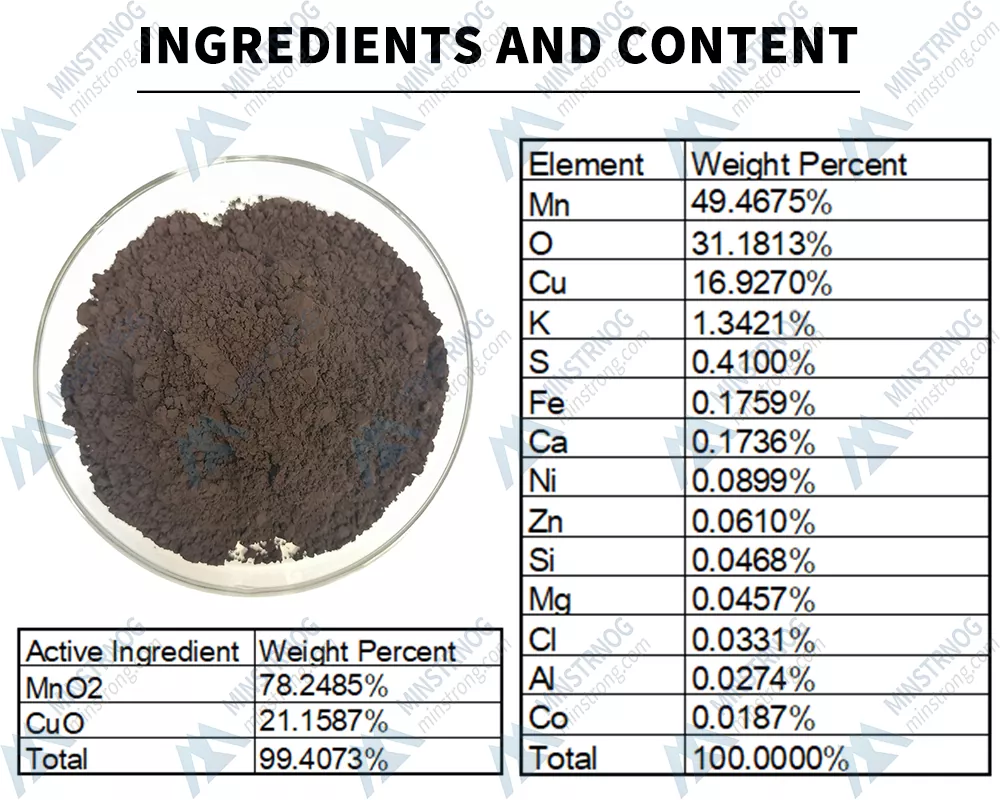

Product parameters

|

Technical Data

|

|

Type

|

Powder

|

|

Color

|

Black/Brown

|

|

Main Ingredients

|

Manganese dioxide, copper oxide

|

|

Active Effective Constituent

|

>95%

|

|

Manganese-copper molar ratio

|

2.5:1- 3.5:1

|

|

Moisture

|

<3%

|

|

Particle size

|

1-20 um

|

|

Specific Surface Area

|

160-260 m2/g

|

|

Density

|

0.2-0.3 g/ml

|

|

Note: Catalyst specification parameters can be customized according to requirements.

|

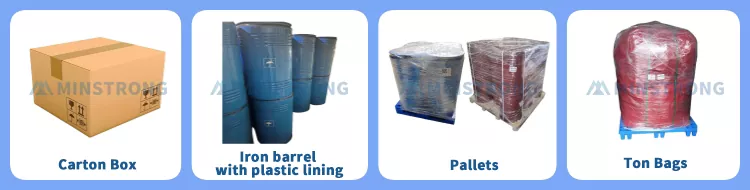

Minstrong Catalyst Packing & Delivery

General Packing: 12.5 KG/40 KG in iron barrel,200 KG in ton bags, all with moisture-proof plastic bag inside, Packing based on user's needs..

For quantity below 2 tons, Minstrong can deliver the product within 7 days.

Shipping Port: Shanghai/other port as request

Air transportation, ocean transportation, railway transportation and truck transportation are available.

Technical Support

-

Minstrong can provide you with professional catalyst application consultation, and design a reasonable exhaust gas treatment solution based on Minstrong's high-performance catalyst;

-

Minstrong can guide you in the design of process and equipment for free;

-

Minstrong can provide you with the construction of test equipment, as well as the design, manufacture and installation of supporting catalytic reactors;

-

Minstrong can provide you with on-site catalyst loading and debugging guidance.

Questions You May Care About

-

Can be shipped to our country??

We can sell in large quantities to global regions including Europe and the United States. MINSTRONG has obtained the license.

-

What should I do if I don’t know how to use the catalyst?

We can provide you with guidance on how to use the catalyst.

-

How can I contact Minstrong?

Email: minstrong@minstrong.com

Whatsapp & Wechat: +8618142685208

Mobile: 0086-18142685208

Skype: ppxxm0417

minstrong

minstrong minstrong

minstrong