Product Introduction

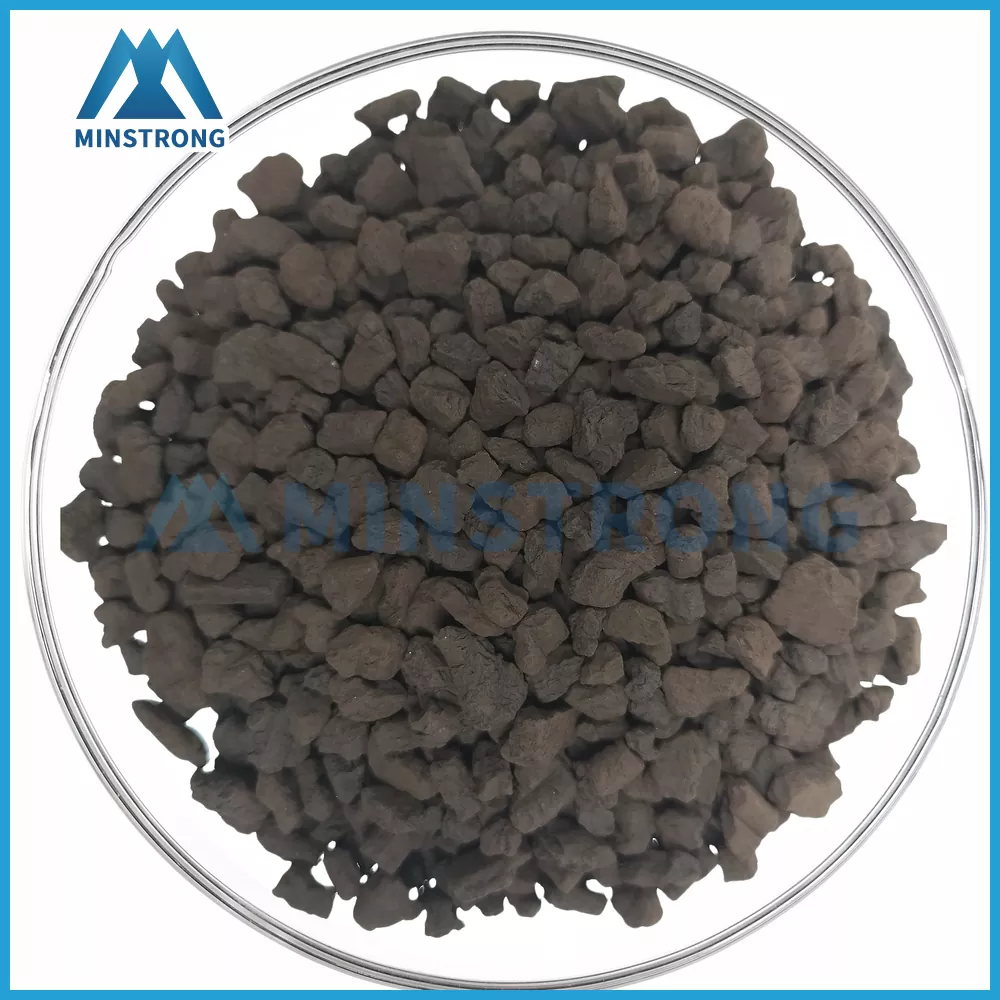

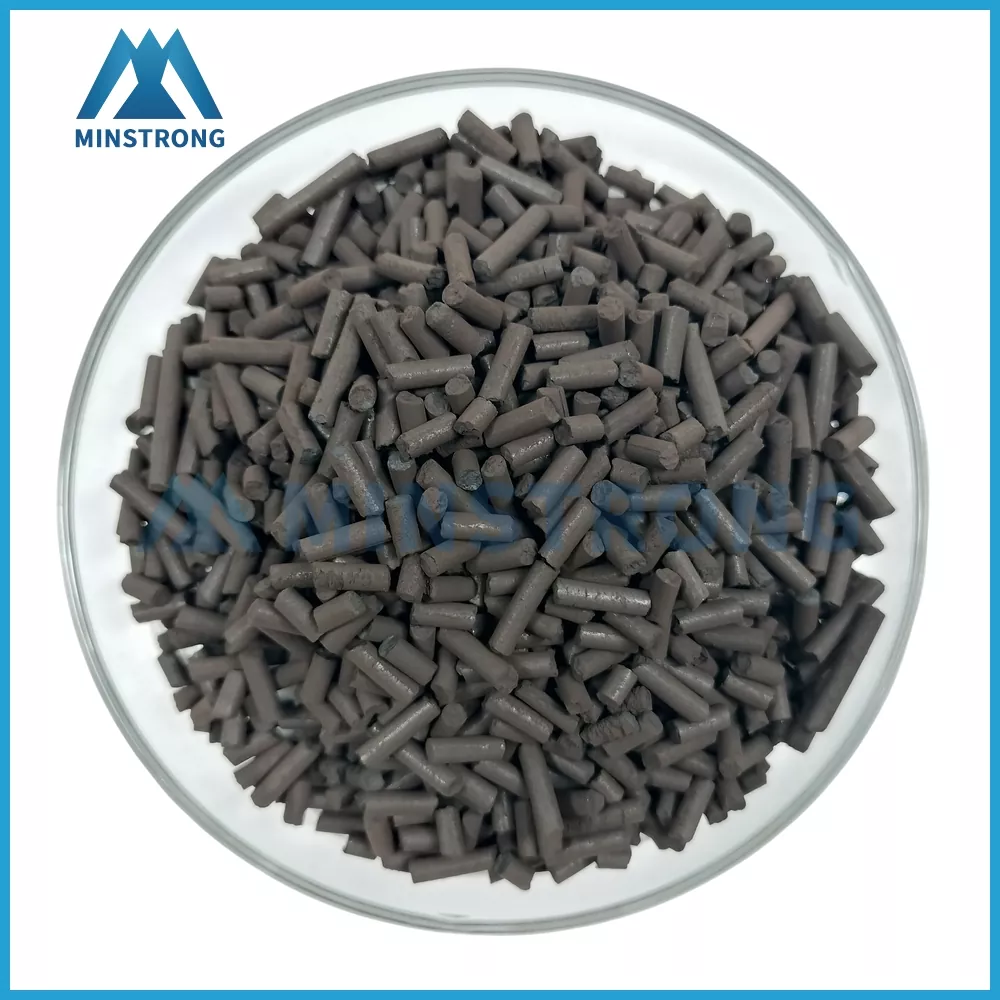

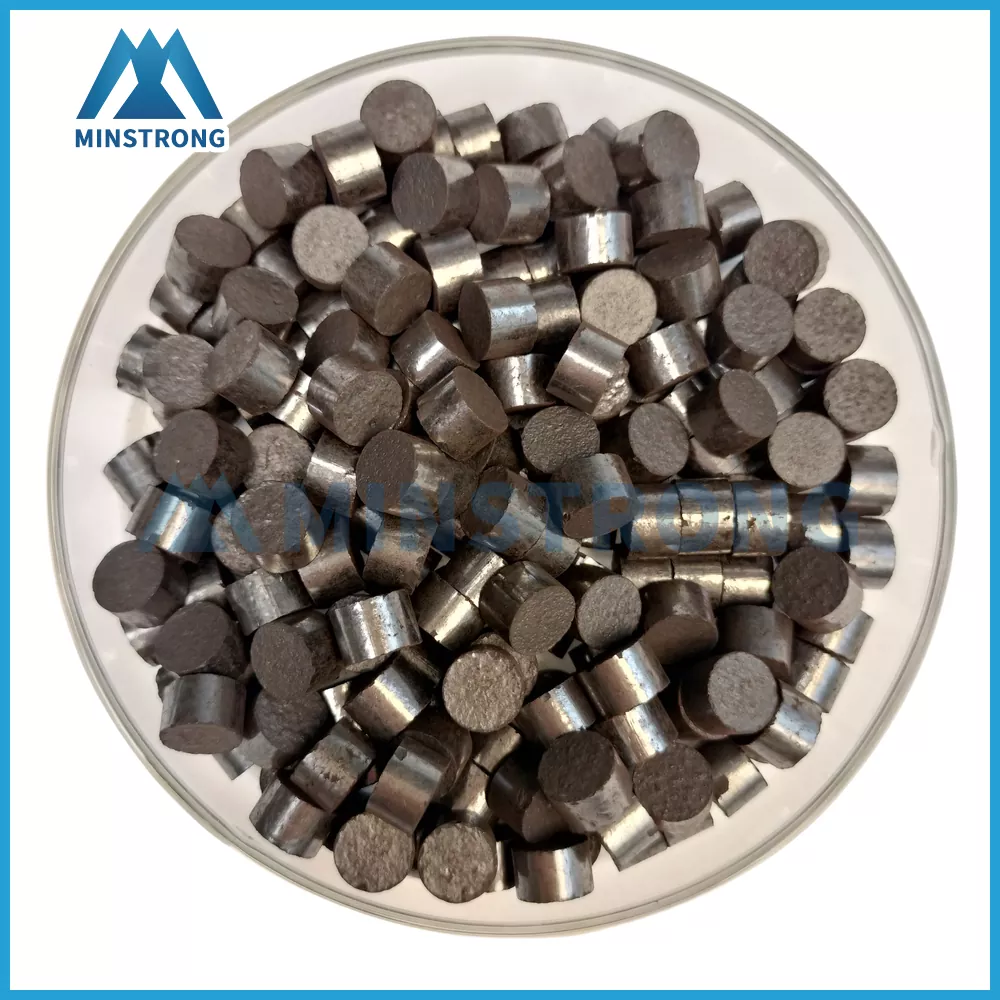

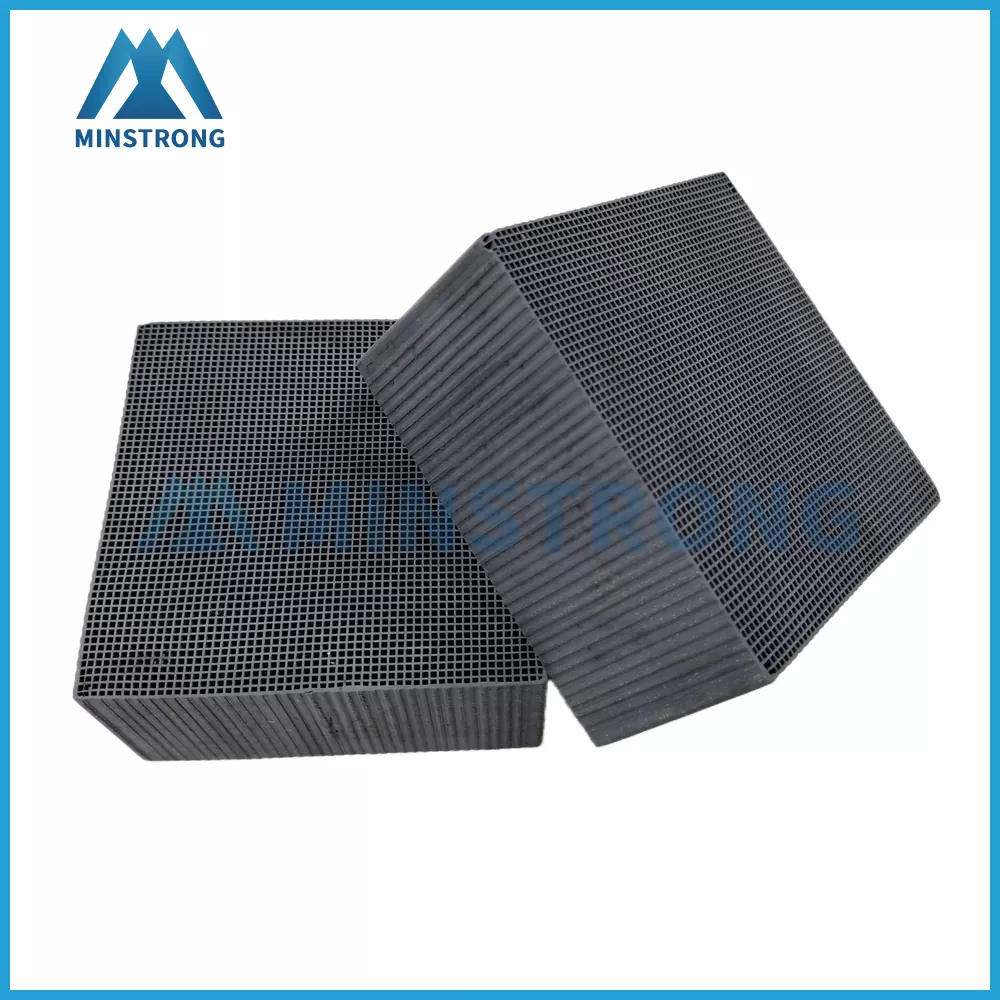

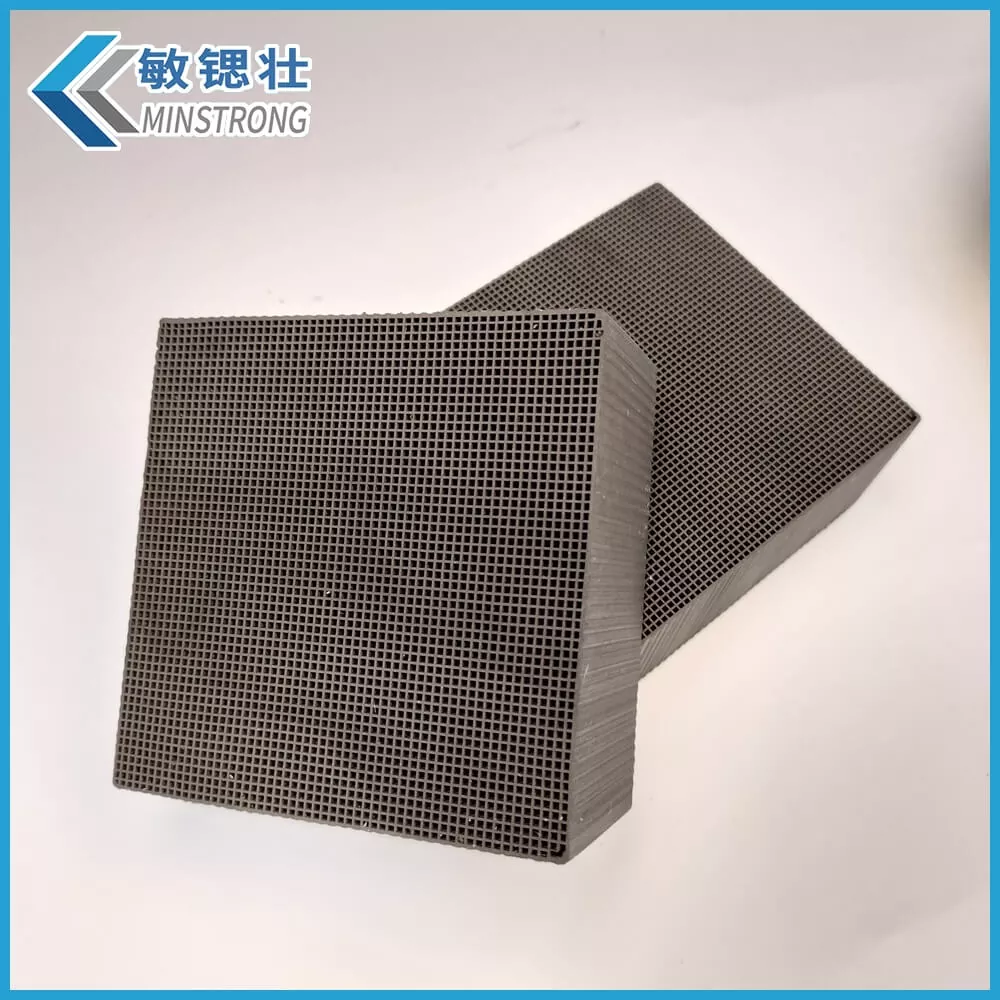

Minstrong ozone destruction catalyst can efficiently decompose ozone into oxygen, eliminate ozone odor, and achieve exhaust emission standards. Minstrong uses chemical synthesis method to manufacture active components, and precisely controls each process parameter of the synthesis reaction. Aluminum oxide is used as a bonding agent. The active ingredient content of Minstrong ozone destruction granule and pellet catalyst is higher than 85%. The ozone destruction catalyst powder does not contain binders, and the active ingredient is as high as 99%.

The catalyst does not contain activated carbon, which can withstand high temperature when dealing with high-concentration ozone. The catalyst does not burn, has no volatility, which is safe to use, and does not cause secondary pollution.

Product Features

-

Minstrong catalyst has good strength, and the average crushing strength is greater than 60N/cm;

-

The specific surface area is high, with a specific surface area 160-240m2/g, and a large number of microporous structures are distributed inside the catalyst, which can effectively absorb ozone and carry out catalytic decomposition;

-

Minstrong catalyst is resistant to high temperature and does not contain flammable and volatile components. When dealing with high-concentration ozone, there is no risk of combustion and no secondary pollution;

-

The content of active ingredients is high, the content of catalyst active ingredients is as high as more than 85%, the performance is stable, the life is long, and it is not easy to lose;

-

The raw materials and production process of the catalyst production are completely independent and controllable, and can be supplied stably.

Applications

-

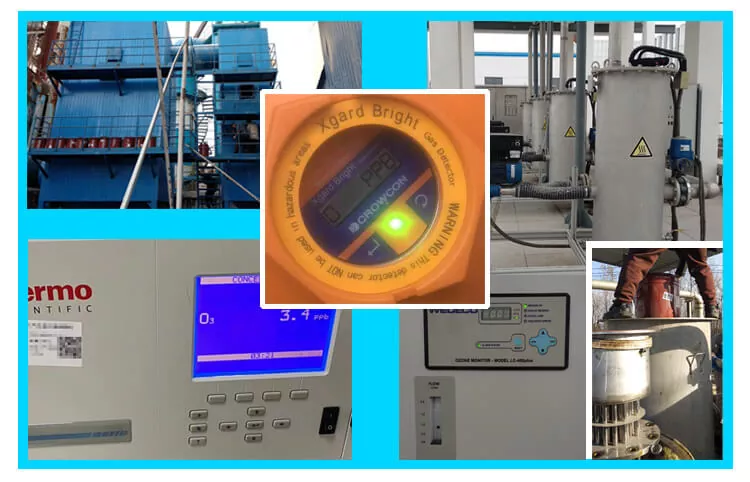

Ozone decomposition for ozone destructor in the ozone water treatment, and the tail gas reaches the standard discharge;

-

Decompose ozone tail gas in ozone disinfection equipment, eliminate ozone odor, and avoid ozone pollution;

-

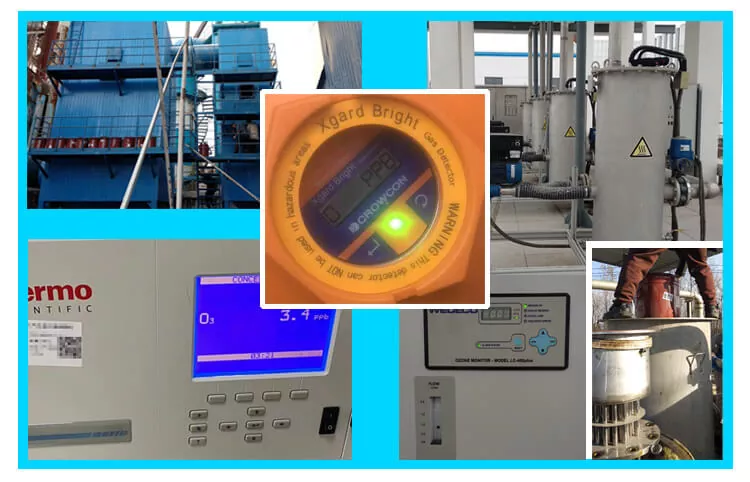

Ozone analysis instrument zero calibration and tail gas decomposition, realize automatic zero calibration of the instrument, no pollution discharge of exhaust gas;

-

Decompose ozone in printing workshops and other spaces where ozone is generated, eliminate ozone odor, and protect the health of personnel;

-

Purify trace amounts of ozone in ozone degerming rooms, ozone disinfection cabinets, museums, libraries and other places, to protect materials and cultural relics from the influence of ozone;

-

Decompose ozone tail gas in other occasions where ozone is applied.

Product parameters

|

Ozone Destruction Catalyst Technical Data

|

|

Type

|

Particle Granule, Pellet Columnar, Powder, Honeycomb and Spherality Ball type

|

|

Active Effective Constituent

|

85% min

|

|

Strength

|

60 N/cm min

|

|

Specific Surface Area

|

160-260 m2/g

|

|

Density

|

0.7-0.9 g/ml

|

|

Temperature

|

0-500 ℃

|

|

Space Velocity

|

1000-80000 /h

|

|

Ozone decomposition ability / Hour

|

≥ 800.0 mg/g

|

|

Ozone decomposition efficiency

|

>99% (The outlet ozone concentration is less than 0.1ppm)

|

|

Note: Catalyst specification parameters can be customized according to requirements.

|

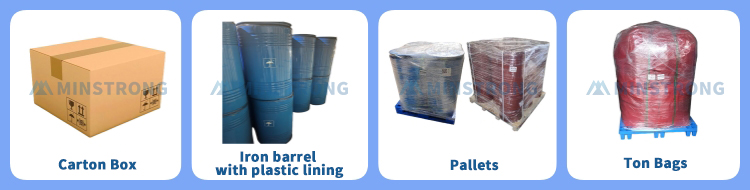

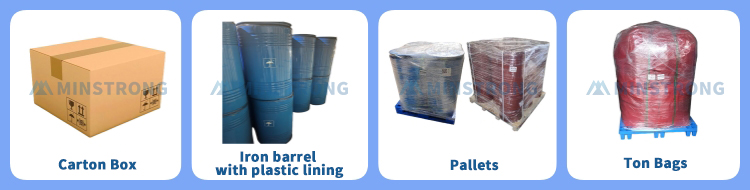

Ozone Destruction Catalyst Packing & Delivery

General Packing: 25 KG/30 KG in iron barrel with moisture-proof plastic bag inside, Packing based on user's needs.

For quantity below 2 tons, Minstrong can deliver the Ozone Destruction catalyst within 7 days.

Shipping Port: Shanghai/other port as request

Air transportation, ocean transportation, railway transportation and truck transportation are available.

Technical Support

-

Minstrong can provide you with professional catalyst application consultation, and design a reasonable exhaust gas treatment solution based on Minstrong's high-performance catalyst;

-

Minstrong can guide you in the design of process and equipment for free;

-

Minstrong can provide you with the construction of test equipment, as well as the design, manufacture and installation of supporting catalytic reactors;

-

Minstrong can provide you with on-site catalyst loading and debugging guidance.

Questions You May Care About

-

How do I determine the specification and dosage of the catalyst?

According to your working conditions, we can select catalysts with appropriate specifications and calculate reasonable dosages.

-

How can I compare the cost of catalyst?

Catalysts are not consumable materials, and are generally calculated according to volume. It is necessary to calculate the comprehensive cost of catalysts based on important factors such as specific gravity, catalytic efficiency, and service life, and at the same time assess the technical and service capabilities of suppliers to prevent after-sales risks

-

What should I do if I don’t know how to use the catalyst?

We will design a reasonable process flow according to your working conditions, and provide you with one-stop services such as catalyst selection, test plan formulation, device design and manufacture, and on-site commissioning.

-

How can I contact Minstrong?

Email: minstrong@minstrong.com

Whatapp & Wechat: +8618142685208

Mobile: 0086-18142685208

Skype: ppxxm0417

minstrong

minstrong minstrong

minstrong